About Us

Your value add partner..

We are CRECHORD INNOVATIVE TECHNOLOGY, a leading provider of cutting-edge mechanical engineering – Design & services talented to provide engineering solutions and enhance your product excellence.

Crechord team delivers world – class end -to-end by leveraging our deep industry knowledge and innovative approach. we can solve problem better faster with multidimensional approach for any critical challenge’s across the aerospace and defense, automotive, energy, healthcare and other industries.

We carry out complex projects from the initial idea to the industrialization, through the different stages of analysis, study, design, calculation and prototyping.

Initially, we were developing different categories of products for the automobile and medical industries, as well as agricultural equipment.

Around 2015 to 2018, we made car seating systems like Latch, Recliner, and Tracks, which included load calculation, effort calculation, and stack-up analysis, and made prototype products and submitted them to relevant customers. At the same time, we conducted tractor body reverse engineering and built a new body with respect to customer requirements. And in the same period, we have done so many plastic parts from scratch up to production planning.

1. Arecanut Husk Removel Machine (Agricultral Equipment): In that machine, the customer came with negative expectations because they had been cheated by other people . At that time, we hadn’t registered the company; we were doing it as freelancers. In that circumstance, we resolved their problem and built that machine without any expectations and without any profit because they were humble farmers.

2. Pesticide bottle Making machine (Medical equipment): At that time, the customer was experiencing a loss of business, and they needed an upgraded machine to sustain their business. However, they didn’t have enough investment to buy an imported machine. During that time, we took on a challenge, conducted extensive research about the machine, and created a design within their budget. We optimized many aspects, such as material selection, manufacturing processes, post-treatment techniques, etc. Now, they are running their business happily and healthily.

In 2019, we started an institute called ‘VISTRUTA GROUP’. There, we used to teach CAD design software and drawing, product manufacturing, and prototype building for BE, ITI, and diploma students.

Around 2019 to 2022, We got an opportunity regarding an edible cutlery making machine with high capacity production. At that time, they were also struggling to identify a specific machine manufacturer, but they didn’t find perfect machine makers. They approached us to make the machine because they knew about our strengths. We also took it as a big challenge to make that machine, and that journey was very tough for us, sometimes being restless and sometimes facing food loss.

Every day we faced new challenges. In that time, we referred to books, the Internet, and some expertise, like scientists, to know about baking technology and their reactions over time and at different temperatures. Within 8 months, we made an edible cutlery-making machine at a very reasonable price. During that time, they were happy, but we couldn’t reach the required production capacity. At that time, we considered that our machine had failed. Then, we renovated most of the points in the machine and built a wonderful machine.

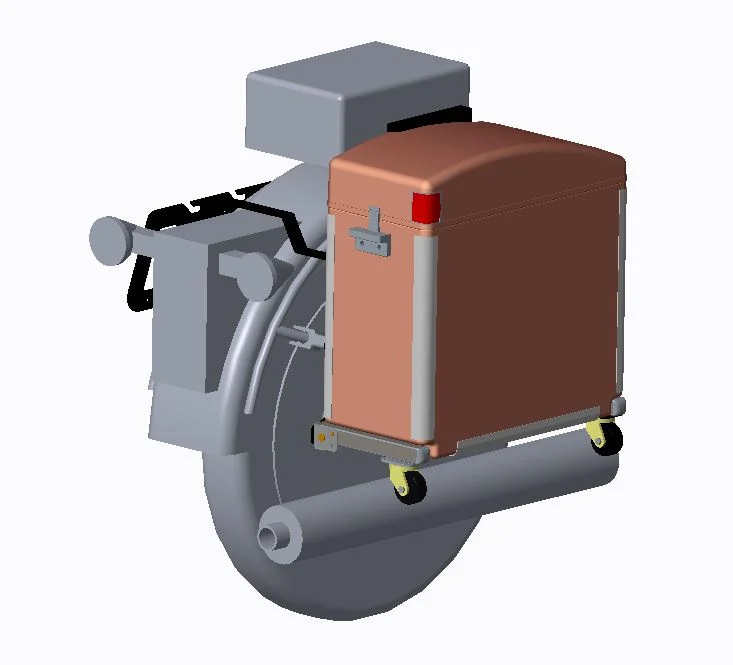

In the year 2023, we made a project for the aerospace industry, and we also provided services to the company. As a third party, we developed a new product for Boeing and Legrand companies. Initially, we focused on the Boeing project only, but in the discussion, we understood that there was a problem. They were actually struggling to identify the mistakes in the machines and the assembly sequence control unit. The control unit will be part of the fuel filling control unit. At that time, we addressed the technical points, and at the same time, the aerospace company was struggling to develop a new product from Legrand. We completed the Boeing project within the given time. At that time, the aerospace company sought our support to develop the new product.

We started as a freelancer in 2018 and we provide design and manufacturing service. And at the same time we started training on how to visualize a product with the help of CAD and how to create a product that includes the manufacturing process.

- CAD Conversion

- Revers engineering

- CAD Clean-Up

- Sheet metal and plastic part design

- Design Training & Placement service

- Load Calculation and FEA

- Injection Mould design (2plate and 3 plate mould)

- Building rapid Prototype

- DFM with respect to customer requirement.

- Manufacturing support.

- Special Purpose Machine(SPM) for Industries.

- Assembly Line Automation

- CAD Automation

- Food process Machine Design and Manufacturing

- Automotive Seating Design (Latch & Recliner)

- Stack-Up Analysis & Load Calculation

- New Product Development(NPD)

- Jigs & Fixtures Design and manufacturing service for Aerospace industries

- Employment Service (Design Engineer)

- Design Consultant for manufacturing Industries

- VAVE Service

- DFMEA & PFMEA